Experienced Liquid Nitrogen Pipefreezing Services

Don't Drain It, Freeze it!

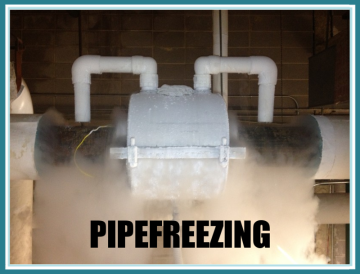

The process of pipefreezing involves the local application of a refrigerant to the outer wall of a section of pipeline to freeze the liquid contents of the pipe, thus forming an ice plug allowing

repairs or modifications to be carried out. By employing the pipefreezing process the complete system does not have to be drained and, in some cases, can continue to operate without interruption.

Pipefreezing, or line freezing, using liquid nitrogen is industry proven and has been used for more than 30 years in North America. Our system can use nitrogen from large or small sources, such as a

tanker truck or 50 gallon vessels, letting us perform pipefreezing in any location. We start by placing a liquid tight metal jacket around the pipe at the place of isolation. Filling the metal jacket

with liquid nitrogen (which has a boiling point of -320.4°F), ice forms within the boundaries of our jacket starting from the pipe wall growing inward. Nitrogen is continuously fed to our jacket and

temperatures are monitored throughout the freeze process to insure safe working conditions wether you are replacing a butterfly valve or brazing a new male adapter.

We provide professional and quality solutions for contractors so that they may offer a superior service to meet their customers needs. Pipefreezing eliminates the need for a costly drain down,

and its related problems, as well as being the environmentally sustainable alternative. The goal of pipefreezing is to keep systems running efficiently for longer, with little or no interruption to

production, while piping system maintenance and upgrades are carried out.

Pipefreezing Video

Capabilities include: 1/2" - 48" pipe size with up to 4,000 PSI.

General Conditions For Successful Pipefreezing:

- The pipe is in good condition and suitable for Pipefreezing applications

- The absence of flow is necessary to achieve successful isolation

-

The line must be full of product for successful isolation

Advanced Flow Technologies technicians have specialized in Pipefreezing services for over 20 years. Regularly used in the construction industry as a cost efficient and time efficient alternative by preventing long hours of draining, filling, and venting a system for maintenance. This also keeps a loss of product from piping to a minimum. Our professional Pipefreezing services can be carried out all over the world. We will travel for your Pipefreezing needs. Don't Drain It, Freeze It.

Pipefreezing Pictures

Advantages Of Pipefreezing

- Branch Lines Can Easily Be Isolated Leaving A Main Line Operating

- Never Draining Large Systems For Repairs

- Keep From Draining Expensive Chemicals Out Of A System

- No Venting or Purging When Refilling System

- No Bulk Storage or Transporting of Materials Drained From A System

- Avoid Creating Leaks When Putting Pressure Back Onto An Entire System

- Does Not Require Bulky Permenant Alterations To Piping

- 100% Isolation With No Bleed By While Welding or Soldering New Joints

- Set Up Of Pipefreezing System Is Done Quickly and Same Day Freeze Is Performed

Applications For Pipefreezing

- Repair or Replace Faulty or Leaking Valve

- Replace Broken or Pitted Piping

- Isolate Fixtures or Rooms That Do Not Have Isolation Valves

- Conserve As Much Chemical In A System As Possible By Reducing Draining

- Keeping a System Running While Making A Repair on A Branch Line

- Avoid Draining A Riser For Maintenance or Repair

Texas State Board of Plumbing Examinars

P.O. Box 4200 Austin, TX 78765

512.458.4200

Master Plumbing license: RMP-20380

Texas Department of Insurance

State Fire Marshal’s Office

333 Guadalupe Austin, TX 78701

512.676.6000

SCR-U-1870257